Rystad Energy assesses that it is metallurgical issues that risk undermining Gazprom’s plans to support development of Iran’s offshore gas fields in particular. Both Iran and Russia are under sanctions from Europe and Japan, as well as others. This means that no Japanese or European oil country tubular goods (OCTG) or steel manufacturers can supply either country. It is OCTG producers from these regions that dominate the global supply of corrosion-resistant alloy (CRA) and high-alloy OCTG grades.

Rystad Energy believes it would take a considerable amount of time and investment for Russia’s steel industry to be able to move to significant commercial production of high-alloy grades, with the market being cut off from European billet supply over Russia’s invasion of Ukraine in late February. There would, therefore, appear to be limited scope for quick development of these major offshore sour gas fields until sanctions are lifted.

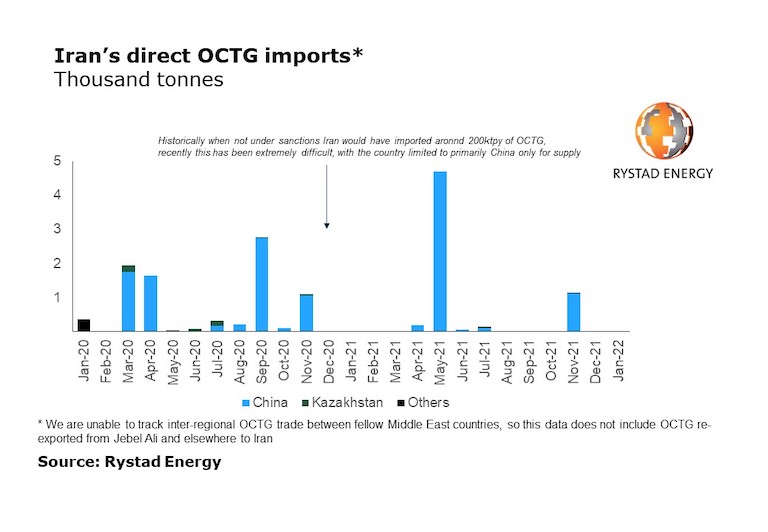

National Iranian Oil Company (NIOC) and Gazprom on 19 July signed a memorandum of understand (MoU) worth up to $40 billion covering the development of several oil and gas projects in Iran. Under the terms of the pact, Gazprom is set to help NIOC in the development of the Kish and North Pars gas fields, provide pressure enhancements to the giant South Pars gas field and help develop six oilfields. This will, however, require CRA and Super 13Cr OCTG tubing grades, which will prove difficult to source given the sanctions currently in place against both nations.

“The corrosive nature of Iranian oil and gas reserves requires high-grade piping for extraction, which neither Russia or Iran have the capacity or capability to produce in the short term. Indeed, the supply chains for these goods are mostly centered in countries applying sanctions on both states. Alternatives, such as Chinese-supplied piping, have reportedly suffered from leakages and other issues. As such, the $40 billion project is facing setbacks from the outset”, says James Ley, Senior Vice President, Analysis

South Pars – a field shared with Qatar, where it is known as the North Field – is the world’s largest offshore gas field and contains highly sour gas that, as a result, is corrosive in nature. The gas is so corrosive, in fact, that all wells being drilled on the field require very high grades of nickel alloy OCTG tubing – for instance, Alloy 28 grade.

Preliminary research suggests that North Pars will also require Alloy 28 or equivalent OCTG tubing grades. The Kish field has two parts – an onshore and an offshore field. The onshore portion is already under development and has been using Super 13Cr tubing grades supplied from China, which can still send material to Iran. However, Rystad Energy understands from market sources with knowledge of the project that some 13Cr that was initially sent to Iran has experienced leakage issues and as a result may have to be upgraded.

The drilling programs planned for both the North Pars and Kish offshore fields are extensive, with the NIOC subsidiary now responsible for North Pars recently deciding to redevelop the field, with plans for four platforms and 32 wells to be drilled. The Kish field falls under the control of NIOC subsidiary Iranian Offshore Oil Company (IOOC) and is divided into two parts. Super 13Cr tubing has been used in onshore drilling activities and IOOC is looking to undertake drilling in the field with a program consisting of two platforms and 11 wells. We understand that Super 13Cr OCTG tubing was being proposed for these wells but that this is now being re-evaluated following onshore leakage issues and the tubing could be upgraded to even higher alloy grades.

With sanctions in place, we do not believe that Russia’s steel industry is currently able to manufacture CRA and Super 13Cr OCTG grades. Small amounts of CRA OCTG grades have been manufactured in Russia in the past, but when leading local mill TMK produced these tubing grades, it had to rely on CRA steel billets being delivered from Europe, which it then rolled into tubing. No Russian steelmaker currently has the capacity and capability to supply these high-grade steel billets to Russian pipe manufacturers. This means there would likely need to be expensive and extensive adjustments made within the Russian steel industry to try to deliver these grades – something that is likely to take years to achieve. With Iran’s offshore gas fields needing relatively high volumes of these super-specialized grades, it is difficult to see how Gazprom can provide any well assistance to develop these fields quickly.

Furthermore, NIOC does not list any Russian OCTG mills as approved suppliers for premium connections. All the offshore gas wells will have to have premium OCTG connections. If the required grade of CRA OCTG were to be produced in Russia and TMK’s premium connection were applied, NIOC would itself have to audit and approve this connection, adding even more time to acceptance of CRA OCTG grades from Russia for the Iranian fields.

For more analysis, insights and reports, clients and non-clients can apply for access to Rystad Energy’s Free Solutions and get a taste of our data and analytics universe.

Follow us on social media: