Part two of a two piece feature on the future of offshore floating wind power in the U.S. with the University of Maine’s Dr. Habib Dagher, the executive director of the University of Maine’s Advanced Structures and Composites Center.

Read part one: Dr. Dagher advocates offshore wind “Marshal Plan” for U.S. ports

Major supply chain dislocations have hampered offshore wind development in recent years but Dr. Habib Dagher, the founding Executive Director of the University of Maine’s Advanced Structures and Composites Center, and an offshore wind pioneer believes they will be solved.

In an exclusive interview with AJOT, Dagher said that supply chain issues “...have surfaced … throughout the construction industry, not just through offshore wind … since the pandemic … What we hope is … the industry is recalibrating right now to try to figure out … how to meet some of the goals. The U.S. has a goal of 30 gigawatts by 2030 of fixed bottom wind turbines. In addition, another 15 gigawatts of floating wind are projected by 2035. So … there's a 45 gigawatt projection between now and 2035 in the U.S. … Certainly there are risks of delays now because of the supply chain issues (but) eventually the wind farms will be built, it's just a matter of time. I don’t think it is going (to) be exactly by 2035 or 2030 … that's the question that remains.”

Technological Innovations Could Simplify Supply Chain

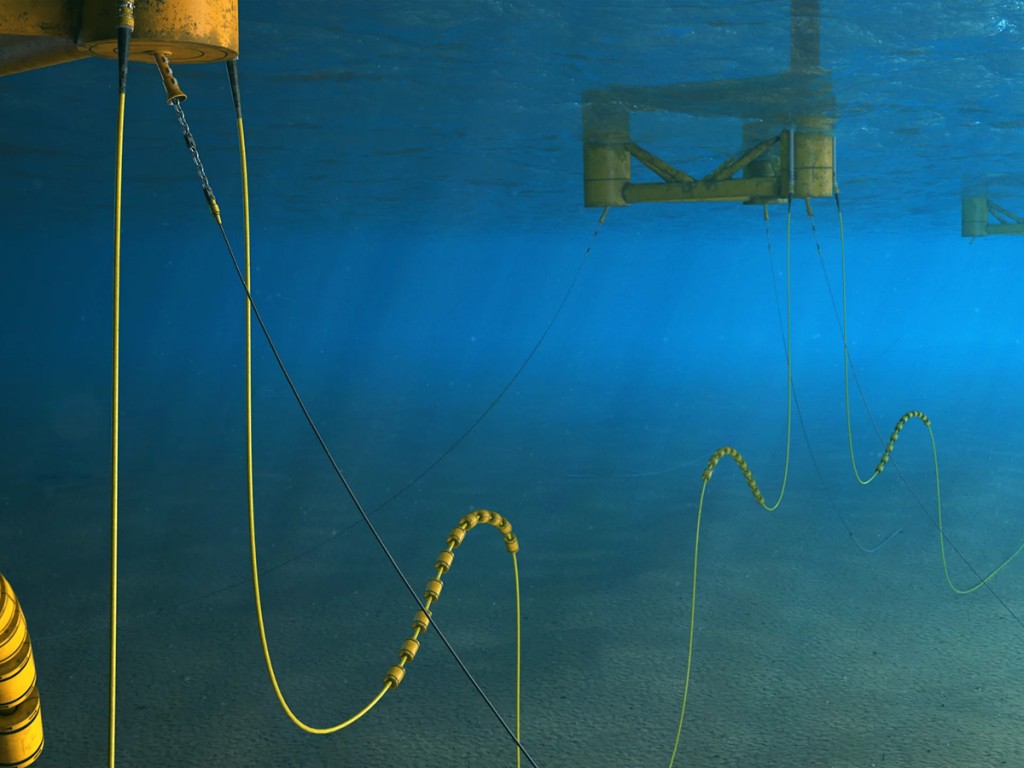

Dagher said one example of new technology that could simplify the production and supply chain process is the introduction of synthetic anchor handling lines replacing anchor chains made of steel to anchor floating wind turbines in several thousand feet of water: “There are two types of anchor chains for anchoring the floating wind turbine. There are the steel chains and synthetic mooring lines. The synthetic mooring lines … are a lot lighter than the steel chain and a lot easier to handle. Capacity is being ramped up right now globally to produce these synthetic mooring lines. There is not enough capacity globally right now to just … manufacture steel chains … if we're going to meet our goals within the timelines and deployment timelines. So, the industry has stepped up and in Europe, companies are building facilities to produce synthetic mooring lines. I would say these floating deep-water units will be using synthetic systems, not steel chains.”

Dagher proposes offshore wind turbines be built on concrete foundations or hulls. The advantage of the concrete hull is that the design will allow for construction at U.S. shipyards by U.S. workers and not require sourcing the foundations from an offshore shipbuilder. The hull can be launched from a fabrication yard in 25 feet of water, which makes the process adaptable for construction in many shallow draft locations.

The University of Maine’s so-called VolturnUS hull design utilizes a concrete semi-submersible floating hull and a composite material tower. Once the hull is launched, the tower and turbines can be added, and the complete installation floated out to sea for anchorage and wind power generation. Dagher says this process could avoid building steel hulls which would be a simpler process: “Using concrete for the hulls of the wind turbines, we do not have to weld, right? So, we pour concrete into molds and then we can build the hulls locally instead of sourcing the steel work to a foreign shipyard … Concrete can be produced locally more easily than steel hulls …and that technology already exists.”

Operational Advantages of Floating Wind Turbines

Dagher noted that there are challenges for fixed bottom wind turbines being built on the U.S. East Coast: “You need jack up vessels that are able to carry the turbine and tower and place it on a fixed foundation. Those vessels are big and expensive … and some of them are getting built in the United States at U.S. shipyards but not fast enough.”

The problem is less severe for the floating wind turbines: “The good news is we don't need the same vessels. We don't need complex vessels like that. We need anchor handling vessels. We also need vessels to tow the floating hulls to the wind farm site. … You will also need cable-laying vessels to install transmission cable under the seabed, linking the wind farms to shore. You will also need other types of safety vessels … smaller vessels to do that … Many of those vessels exist in the U.S. already.”

In another innovation the University of Maine’s VolturnUS’s hull includes a tuned mass damper, also known as a seismic damper, a device mounted in structures to reduce mechanical vibrations.

Dagher said the technology allows “us to reduce the size of the hull. The hull does not move as much in the water … And when the extreme waves come in … we're able to dampen the … motion significantly. We are able to build a smaller hull plus the hull design has been simplified. It's easier to build and our goal is still to build it locally, so to create local jobs in the U.S.… and that allows us to reduce the whole weight mass.”

Dagher also notes the need for dynamic cables: “We will need what is called dynamic cable which transfer(s) electricity from the wind turbine that moves with the hull and links up with the transmission cable, which is a static cable on the seabed floor. Producing these dynamic and static cables is a real opportunity for manufacturing in the United States.”

The U.K. based firm TechnipFMC says it has supplied dynamic systems to the oil and gas industry for 30 years and dynamic power cables for 25 years according to its website. The company says the problem that might be relatively easy to solve on a bottom-fixed wind farm becomes a different and more complex one on a floating offshore wind turbine: “There will be multiple cables connecting multiple floating wind turbines together, transferring power from each wind turbine to the other floating wind turbines and eventually to a fixed, non-floating substation.”

Therefore, it is vital: “ensuring that the Dynamic Inter Array Cable is manufactured without any inherent defects.” That means ensuring: “the building blocks of the Dynamic Inter Array Cable System are being optimized, there is already control of schedule and reliability and cost risks are managed. There won’t be cost inflation due to poor scheduling, downtime, service or installation failures or manufacturing defects.”

The company says subsea cables, responsible for roughly 80% of wind insurance claims, “are seen to be the element with the highest risk for failure. The move to floating offshore wind is expected to increase the losses and associated costs. Management of the inherent risk of subsea cables is arguably the greatest benefit using a Dynamic Inter Array Cable System has to offer.”

Inflation and Financing

Dagher believes inflation caused short term disruptions to offshore wind development but a new recognition of factoring inflation into Power Purchase Agreements is recognized and will restart developments: “The big issue we faced is that while projects were secured with Power Purchase Agreements (PPAs) they were obtained prior to the pandemic and did not include an inflation adjustment as part of the purchase agreement. So, when the inflation went up so high … you got more than 40% inflation since the pandemic, sometimes in some cases up to a 100% inflation, depending on the products. What happened is the Power Purchase Agreement that existed prior to the pandemic … was no longer sufficient to cover the costs. Unfortunately, there was … no … foresight in these agreement(s) that said, ‘we'll agree to pay for inflation.’ The public partners who were buying the energy, which were essentially in-state entities or public utilities commissions and others, did not include an inflation adjustment in some of these contracts. The good news is the new contracts are being worked on right now. People understand that … and they're starting to include inflation … (Also) inflation is starting to stabilize. So … what we learned from all this is that … we (are) … very sensitive to inflation because we're a capital-intensive industry, … and therefore inflation really needs to be front and center in Power Purchase Agreements...”

Dagher notes: “The big developers … have brought some of their own equity into these projects and (can) self-finance the development as well as potentially part of the construction of the project … A variety of interested parties including investors, investment banks … actually do these kinds of projects. And they do them in Europe … specialized companies that specialize in offshore wind, and some are specializing also in floating offshore wind financing. So those dollars will arrive.”

Follow us on social media: